SAPP PP Pressed Steel Pillow Block

Normal Duty

Narrow Inner Ring

Set Screw Locking

Bore Sizes: 1/2 inch up to 1-7/16 inches

Documents & Materials

![]() SAPP-Pillow-Block-Pressed-Steel-Eccentric.pdf

SAPP-Pillow-Block-Pressed-Steel-Eccentric.pdf

KML Part Numbering System

Housing Types

![]() Mounted-Bearing-Units-Housing-Types.pdf

Mounted-Bearing-Units-Housing-Types.pdf

Design

KML Bearing USA Pressed Steel Mounted Bearing Units are manufactured to KML specifications in ISO9001 and TS-16949 certified facilities. KML Mounted Bearing Unit housings are made from progressive die stamped steel. KML Pressed Steel Mounted Bearing Unit product line is available in many different housing styles with various attachment methods and positions. Where applicable, all KML Pressed Steel housings come as a complete set ready for insert bearing installation.

The insert bearings’ inner ring, outer ring and balls are produced using vacuum degassed 52100 bearing steel. These components are heat treat hardened to produce a durable wear surface on the balls and ball tracks. KML uses cold rolled steel for ball retainers and shields. The Pressed Steel Mounted Bearing Units almost exclusively use narrow inner ring insert bearings with a flush back face.

The KML Bearing USA Pressed Steel Mounted Bearing Units are generally non-relubricatable. The insert bearing is available in a set screw or eccentric locking collar design that is factory sealed. All KML Pressed Steel Mounted Bearing Units are factory lubricated using Chevron SRI#2 grease with about 30-40% grease fill. Some 3 and 4-bolt hole round flange sets are available with a grease zerk in the housing and a re-lube insert bearing.

Grease Types

Standard Grease Types

KML Pressed Steel Mounted Bearing Units are lubricated with Chevron SRI#2 from the factory. Chevron SRI#2 is a high temperature ball and roller bearing grease. It is formulated using a synthetic polyurea ashless organic thickener with additional rust and oxidation inhibitors. This grease provides superior corrosion protection in severe applications in the presence of both salt and fresh water. The temperature range of the Chevron SRI#2 is -20°F to 350°F (-29°C to 177°C). It provides excellent bearing life at operating temperatures of 185°F to 230°F (85°C to 110°C). KML nitrile rubber seals will begin to deteriorate above 230°F temperature. KML bearing units normal grease content is about one third to one half of the internal space in in the bearing insert. KML Pressed Steel Mounted Bearing Units generally are not relubricatable. They are factory sealed and considered Lubed-for-Life.

Grease Fittings & Set Screws

KML Pressed Steel Mounted Bearing Units grease fittings:

KML Pressed Steel Mounted Bearing Units type PF2xx/PF2xxGP are relubricatable. These 3-bolt round and 4-bolt round flange sets feature a grease fitting in one half of the 2-piece flange set. The grease fitting has a spring loaded ball-check valve. The spring loaded ball-check valve provides a positive seal after grease is pumped into the bearing thereby preventing any back flow and keeping dirt out. The grease fitting should be wiped clean before attaching the grease gun to prevent pushing dirt or contamination into the bearing.

Recommended Lubricants:

Chevron SRI#2 – Normal load ball bearing inserts

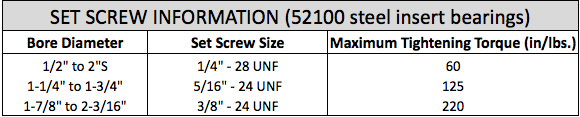

KML Pressed Steel Mounted Bearing Units set screw torque:

Tolerances

Relubrication

Insert bearings in KML Pressed Steel Bearing Units have sufficient high-grade grease installed during assembly. These insert bearings are factory sealed and considered lubed-for-life*. KML Pressed Steel Bearing Units normal grease content is about one third to one half of the internal space inside the bearing. KML bearings are lubricated with Chevron SRI#2 from the factory.

*-Some KML Pressed Steel 3 & 4-bolt round flanges are relubricatable. Please refer to ‘Relubrication’ instructions found in KML Cast Iron Mounted Bearing Units product group for these part types.