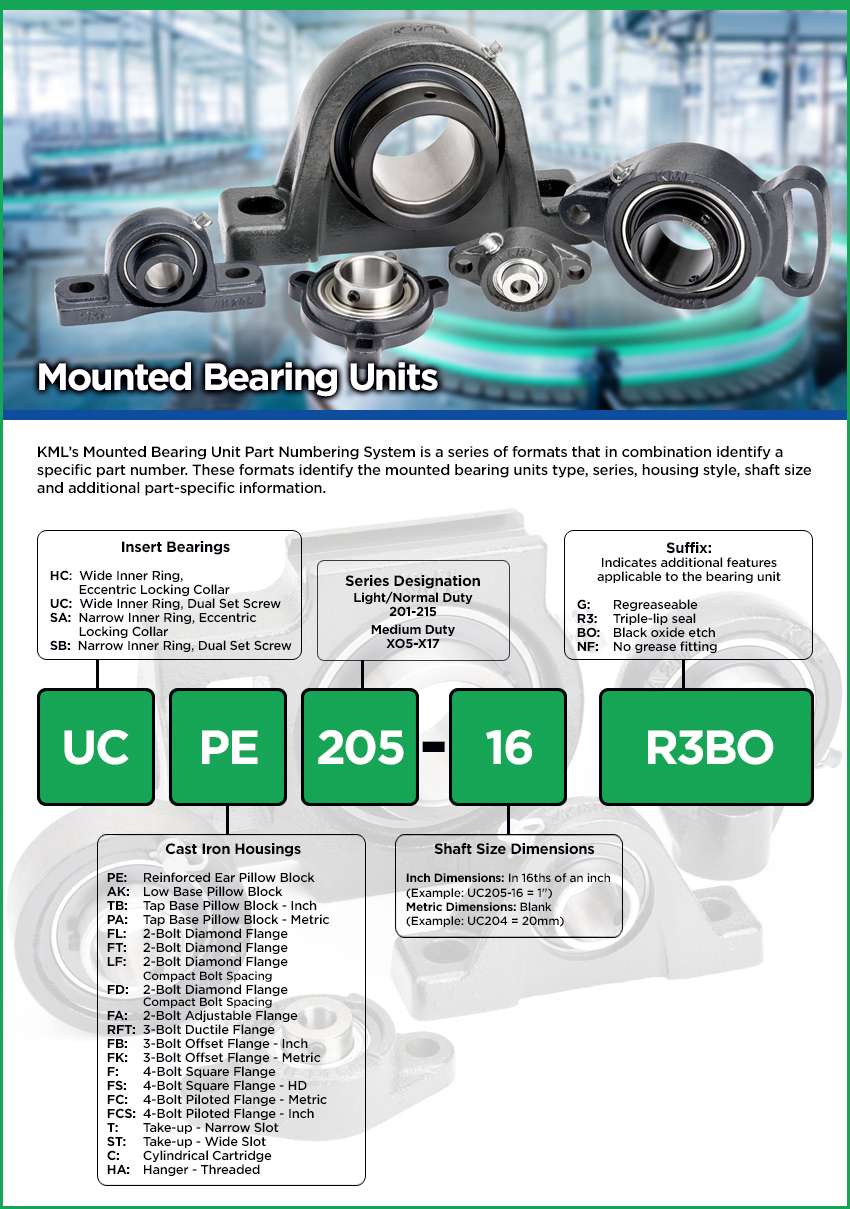

4 Bolt Round HCFC Flange, Wide Insert Bearings

Normal Duty

Wide Inner Ring

Eccentric Collar Lock

Bore Sizes: 1/2 inch up to 2-7/16 inches

Documents & Materials

![]() FC-Flange-4-Bolt-Round-Wide-Inner-Ring-Eccentric.pdf

FC-Flange-4-Bolt-Round-Wide-Inner-Ring-Eccentric.pdf

KML Part Numbering System

Housing Types

![]() Mounted-Bearing-Units-Housing-Types.pdf

Mounted-Bearing-Units-Housing-Types.pdf

Design

Cast Iron Mounted Bearing Units

KML Bearing USA Cast Iron Mounted Bearing Units are manufactured to KML specifications in ISO9001 and TS-16949 certified facilities. KML Mounted Bearing Unit housings are made from high strength cast iron. The housings are designed with solid base construction and reinforced bolt hole areas. KML Mounted Bearing Unit product line is available in many different housing styles with various attachment methods and positions.

The insert bearings’ inner ring, outer ring and balls are produced using vacuum degassed 52100 bearing steel. These components are heat treat hardened to produce a durable wear surface on the balls and ball tracks. KML uses cold rolled steel for ball retainers and shields.

The insert bearing features a labyrinth sealing system that is comprised of a metal backed nitrile rubber excluder seal that is designed to keep grease in and contaminants out. The seal is protected by steel flinger installed in front of the seal contact surface with the inner ring. This flinger, due to centrifugal force during bearing rotation, effectively slings moisture and contaminants away from the seal area. The seal is designed to allow used grease to purge past the seal into the channel between the seal and the flinger when new lubricant is carefully replenished.

All KML Mounted Bearing Units are factory lubricated using Chevron SRI#2 grease with about 30-40% grease fill.

Grease Types

Standard Grease Types

KML Cast Iron Mounted Bearing Units are lubricated with Chevron SRI#2 from the factory. Chevron SRI#2 is a high temperature ball and roller bearing grease. It is formulated using a synthetic polyurea ashless organic thickener and rust and oxidation inhibitors. This grease provides superior rust protection in severe applications in the presence of both salt and fresh water. The temperature range of the Chevron SRI#2 is -20°F to 350°F (-29°C to 177°C). It provides excellent bearing life at operating temperatures of 185°F to 230°F (85°C to 110°C). KML nitrile rubber seals will begin to deteriorate above 230°F temperature. KML bearing units normal grease content is about one third to one half of the internal space inside the bearing. The grease used for replenishment should checked for compatibility before application.

Lubrication Options

KML Cast Iron Mounted Bearing Units can be supplied with alternate solid-lube lubrication options. (Additional lead time required).

KML Solid Polymer 350 – KML offers 350°F (177°C) temperature rating with increased lubrication performance. This lubricant makes relubrication unnecessary while increasing the performance of the bearing with Extreme Pressure additives. In addition, lubricity is enhanced with a Friction Reduction additive making this a truly High Performance Lubrication Option.

Please contact KML Bearing USA Technical Services for more information on this and other lubricant solutions.

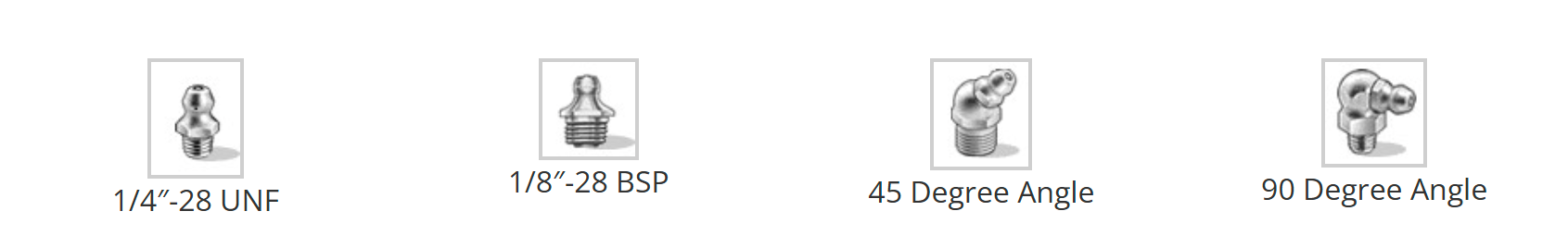

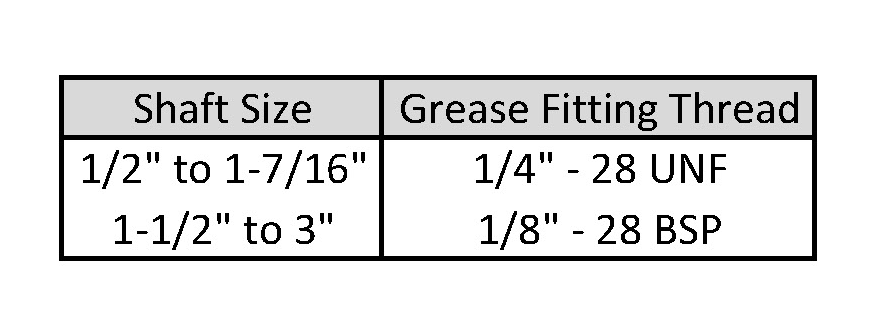

Grease Fittings & Set Screws

KML Cast Iron Mounted Bearing Units grease fittings:

KML Cast Iron Mounted Bearing Units are equipped with spring loaded ball-check valve grease fittings. The spring loaded ball-check valve provides a positive seal after grease is pumped into the bearing thereby preventing any back flow and keeping dirt out. The grease fitting should be wiped clean before attaching the grease gun to prevent pushing dirt or contamination into the bearing.

The grease fitting style varies depending on part type and shaft size. The most common styles and configurations are shown above in the diagrams. Most of the fitting types are able to be visually identified by comparison to the diagram.

General fitting identification by series follows:

Recommended Lubricants:

Chevron SRI#2 – Normal load ball bearing inserts

Mobilux EP 2 – Heavily loaded plain and roller bearings

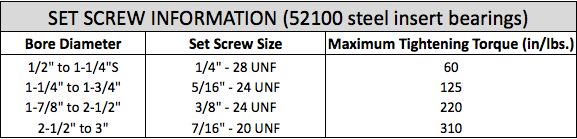

KML Cast Iron Mounted Bearing Units set screw torque:

Tolerances

Relubrication

Lubrication

Insert bearings in KML Cast Iron Mounted Bearing Units have sufficient high-grade grease installed after assembly. There is no need for replenishment during initial operation in new installations. KML bearing units normal grease content is about one third to one half of the internal space inside the bearing.

Re-greasing

The performance of a bearing is greatly influenced by the quality and quantity of the grease. KML recommends a lithium based NLGI #2 grease. In order to avoid over filling, it is advisable to replenish the grease in small amounts. A hand grease gun should only require a few pumps per bearing for most sizes and conditions. Over lubrication is a major cause of bearing failure. Over filling can increase heat build-up in the bearing during operation which can lead to premature failure. Over filling can dislodge seals and flingers from their mounting position thereby interfering with the rotation of the bearing or destroying the integrity of the seal.

KML bearings are lubricated with Chevron SRI#2 from the factory. The grease used for replenishment should be checked for compatibility before application.

Lubrication Intervals

Bearing units are generally relubricatable from the factory. Depending on the operating conditions, relubrication on the bearings is not always necessary where environments are clean and temperatures are low. It is normal to see a small amount of grease at the edge of the flinger during and after operation. Grease deteriorates overtime and should be replenished. Lubrication intervals are a function of the environmental conditions coupled with the operating temperature. General lubrication intervals are shown in THE ACCOMPANYING CHART. There is no substitution for recommendations by the equipment manufacturer and/or observation by operators to determine the appropriate lubrication cycles.